ROBOTIC SPRAYING AND DEPOSITION

PAINT - GLUE - POWDER - THICK PRODUCT

REPEATABLE

UNIFORM

ECONOMIC

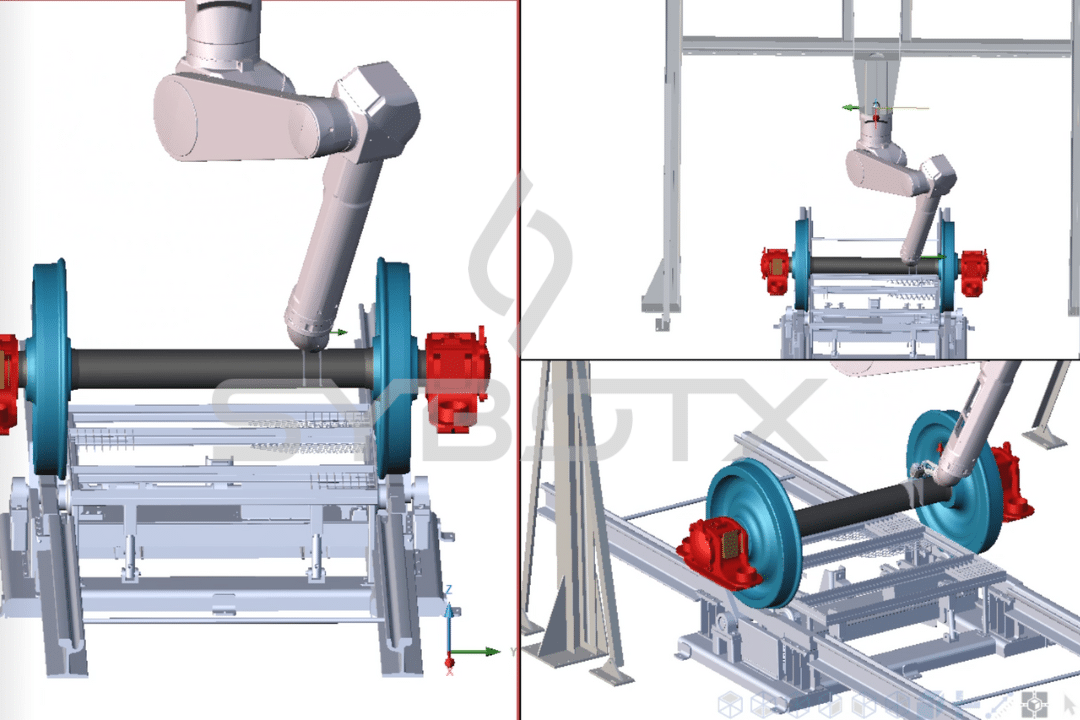

ROBOTIC SPRAYING PROCESS

SybotX, a specialist in spraying and coating, accompanies you in defining your painting robots, regardless of your production volume.

Our engineers analyze your products to determine the robots and equipment suitable for their applications.

We efficiently program them, regardless of the type of robotic sprayer used: automatic guns, rotary bowls, with or without electrostatic processes.

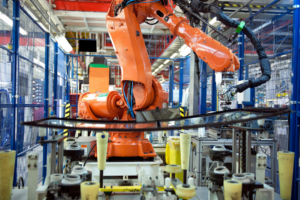

These technologies enable uniform deposition of products such as paints, powders, adhesives, etc., on your workpieces while complying with applicable standards.

APPLICATION EQUIPMENT FOR PAINTING ROBOTS

AUTOMATIC GUNS

Spray and product deposit guns are devices equipped with an automatic mechanism controlled by robot controllers.

They allow precise and uniform application following a predefined program.

Range of guns :

- Air Spray

- Air Mix

- Air Less

ROTATING BOWLS

Rotary bowl spraying is a high-speed spinning process that generates paint droplets.

They disperse from the center of the bowl towards its edges thanks to centrifugal forces, creating a mist of paint.

This uniform distribution allows for a high quality finish.

Products that can be sprayed by bowls :

- Solvent phase paint

- Water-based paint

- Powder

ELECTROSTATIC PROCESSES

Electrostatic spraying is a method of applying coatings where paint particles are electrically charged before being sprayed.

These are attracted to the surface to be coated, allowing uniform distribution of the paint.

Spray range with electrostatism :

- Spray gun

- Bowl spraying

- Powder spray

PRODUCT RANGES APPLICABLE BY PAINTING ROBOTS

PAINT

This finishing layer protects surfaces against chemical and environmental aggressions.

It ensures durability and robustness while preserving an aesthetic appearance on the treated parts.

Family of paintings :

- Shade

- Primary

- Finishing painting

- Corrosion Resistant

POWDER

Dusting is a process in which a fine powder, usually a thermosetting resin, is sprayed. The piece is then passed through the oven in order to permanently fix the powder on the support.

This solid and uniform coating makes it possible to improve the appearance and the protection of the surfaces.

Powder family :

- Insulation

- Decoration

- Release agent

- Corrosion Resistant

GLUE

Spraying or applying glue makes it possible to assemble materials quickly, cleanly and efficiently.

This is a method that is suitable for coating large surfaces or for reaching small and particularly hard-to-reach places.

Family of glues :

- Optics

- Electrical

- Thermal

- Mechanical

THICK PRODUCTS

Spraying or depositing thick products is a process used to seal joints and cracks in materials, applying an adhesive and flexible substance that hardens.

It aims to prevent leaks of liquids, gases and ensure a seal in various industrial applications.

Thick product family :

- Insulation

- Greasing

- Tightness

- Sound-absorbing

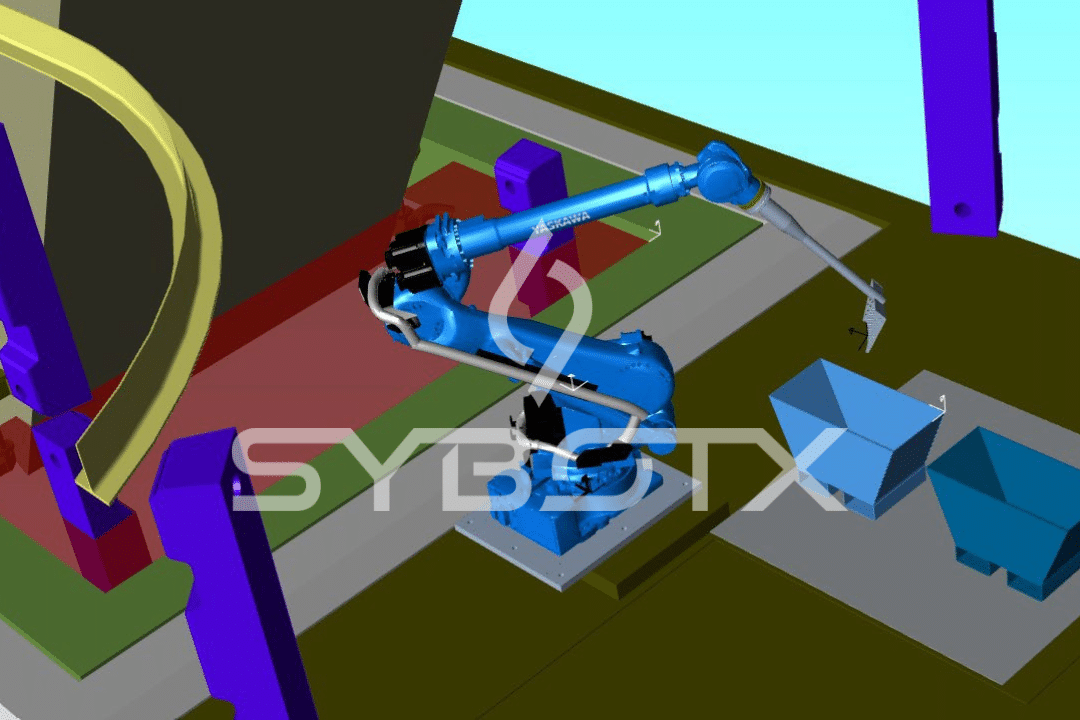

ROBOTS DEDICATED TO SPRAYING AND DEPOSITING

There are several brands of painting robots, the best known of which are FANUC, ABB, YASKAWA, STAUBLI, KUKA, KAWASAKI…

SybotX, your robotic engineering office specialized in spraying and depositing, collaborates and works with many brands.

EUROPEAN REGULATIONS RELATING TO ROBOTIC SPRAYING

The ATEX (ATmosphères EXplosives) regulations are based on two European directives.

They aim to improve the protection and health of workers in explosive atmospheres.

They also cover the devices and protective systems used in these environments.

SybotX implements these regulations and is committed to keeping you informed of your responsibilities as an integrator or manufacturer.

Based on the characteristics of your paints, adhesives, powders, or other products to be applied, we advise you on suitable ATEX-compliant painting robots.

Protective equipment and systems intended for use in explosive atmospheres.

Health safety of workers working in areas at risk of explosive atmospheres.

OTHER GUIDELINES

This Directive concerns equipment intended for use in potentially explosive atmospheres.

It aims to ensure the safety of the products used in these environments.

This directive applies to machines and aims to guarantee their safety and compliance with European standards.

It defines the essential safety requirements for machines placed on the European Union market.

This Directive concerns electrical equipment operating at a voltage between 50 and 1000 volts alternating current, and between 75 and 1500 volts direct current.

It aims to guarantee the safety of low-voltage electrical products.

This directive concerns the electromagnetic compatibility of electrical and electronic equipment.

Aims to ensure the non-disturbance of products in their electromagnetic environment and protection against external disturbances.

This directive applies to pressure equipment such as tanks, piping and pressure vessels.

It aims to guarantee their safety and their compliance with European standards.

This Directive restricts the use of certain hazardous substances in electrical and electronic equipment.

It aims to reduce the risks to human health and the environment associated with these substances.

This Directive concerns the management of waste electrical and electronic equipment.

It aims to reduce the environmental impacts of these wastes and to promote their recycling and appropriate disposal.

This Regulation concerns the registration, evaluation, authorization and restrictions of chemical substances.

It aims to guarantee the safety of chemicals used in the European Union and to protect human health and the environment.